Industrial Radiographic Film IXQ80HD

Brief description:

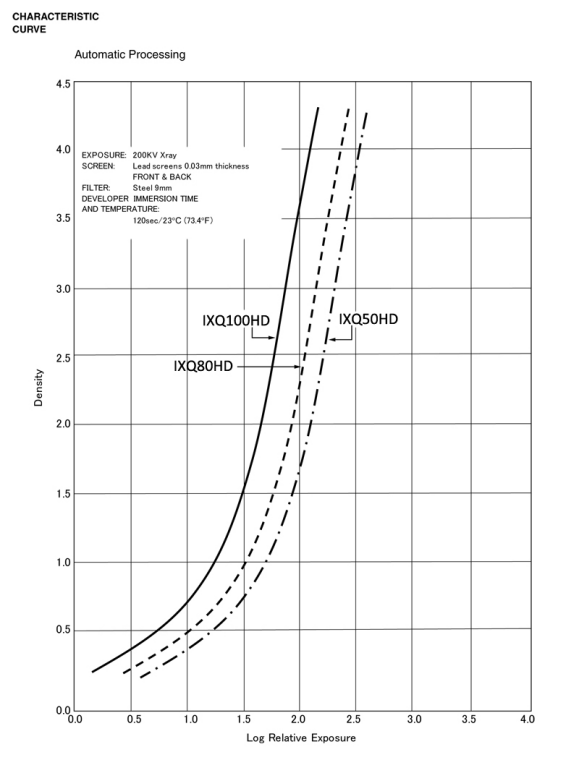

IXQ 80HD is a kind of Industrial radial films; raw films is original Fuji jumbo roll, cut and pack in China, Industrial NDT films IXQ 80HD is used in Non Destructive Testing to object by using x-ray or gamma ray. Industrial NDT films IXQ 80HD is an ideal and wide applied with its characteristics as high sensitivity, high contrast, high clarity and utmost meticulous texture; Industrial NDT films IXQ 80HD is new NDT films: Eco-Friendly HD Series

IXQ 80HD have small granularity, have high detection rate of defect. The coating is evenly distributed. All the lots are stable. Final user can get stable and excellent image without adjusting the exposure condition for different lots.

These films have the High Definition performance even though under exhausted developer.

This performance is more remarkable under manual processing( handy development)

* According to EN-584-1 standard, IXQ 80HD accord with C4 category;

* According to ASTM E1815-96 standard, IXQ 80HD accord with I category

* According to GB/T 19348.1 standard, IXQ 80HD accord with T2 category

* According to ISO 11699-1 standard, IXQ 80HD accord with C4 category

Application field:

* IXQ 80HD can be used to take X-ray image for medium light metal or thin-wall steels /products, under low voltage. If under high voltage, it is suitable to conduct detection for medium light metal or thin-wall steels.

IXQ 80HD is suitable to detect thick-wall and high density steels /products through high-energy Gamma ray.

Application Objects:

Metal, Castings, welding,Aircraft Industries, Electron component, Nuclear industry, Pipeline, Concrete

Film base

IXQ 80HD is made under stable-size grain blue PET base, the thickness is 0.175mm.

Darkroom lighting

IXQ 80HD should be operated under indirect safelight lamp (wavelength>520nm).

Intensity of the light bulb should less than 15W. and place it at least 150cm distance between the reflecting surface and films, or use LED light (wavelength 660nm—590nm)

Developing

l IXQ 80HD is suitable for both of automatic and manual developing.

l Manual (developing time 5 minutes, temperature 20℃)

(fixing time 5-10 minutes, temperature 18-22℃)

Automatic(8-10 minutes, temperature 25℃)

* IXQ 80HD also can be developed by other brand chemicals

Package:

Size Box Unit box/carton

14x17in 100sheet/box 4

Storage of exposed films

Manufacturer guarantees the storage time for permanent film as 50 years, but should observe follow term:

* Films should be developed cleanly and with best photographic fixing.

* Films should be stored under the relative humidity condition between 40%--60% and away from harmful gas.

Storage for unexposed films

Unexposed series films should be stored into original light-tight package and in dry place, low temperature as much as possible, keep away from aggressive steam & gas, harmful gas and any other ionizing radiation.

The ideal storage temperature should be 10℃--24℃, Air humidity 40%--60%.